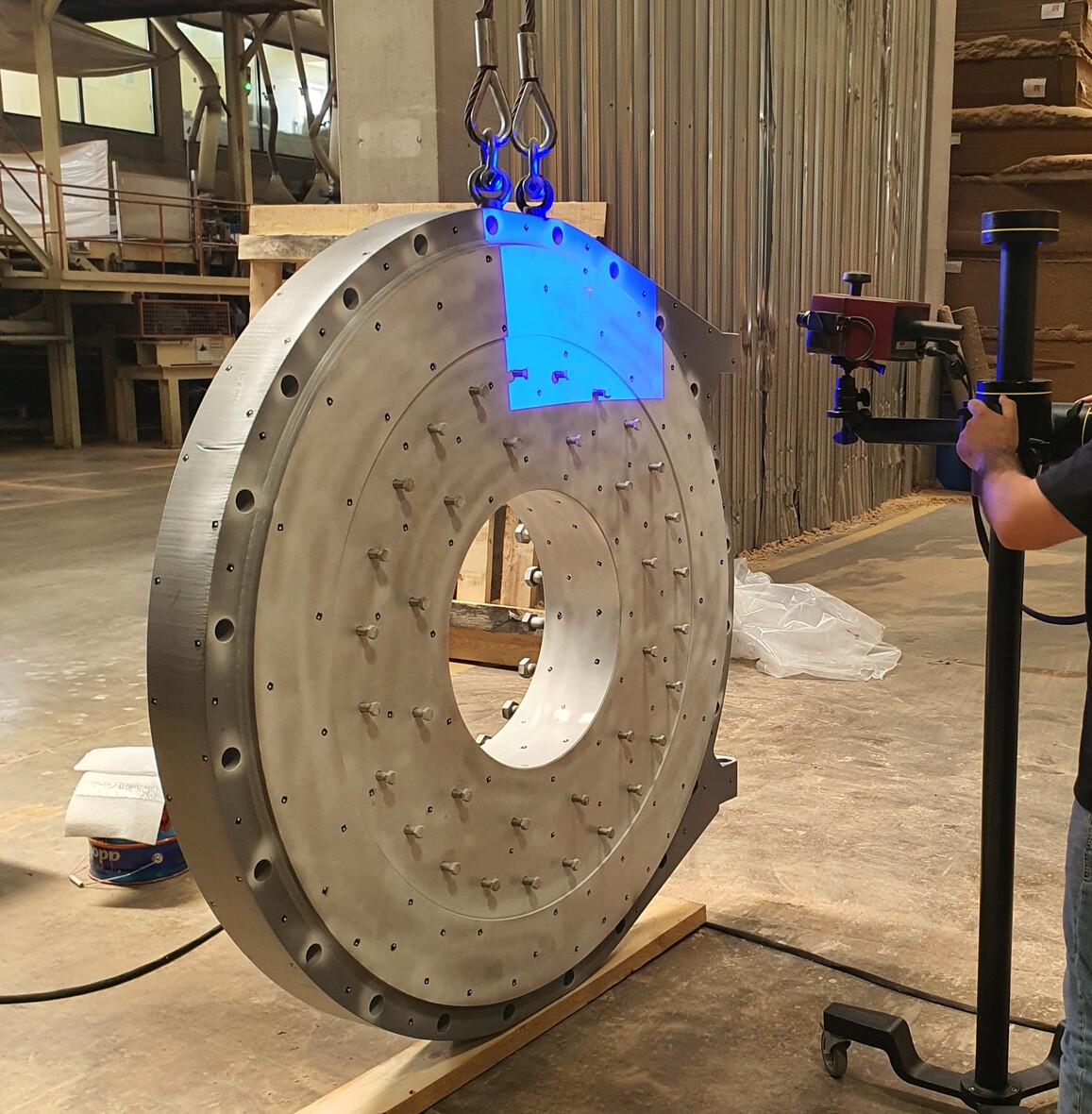

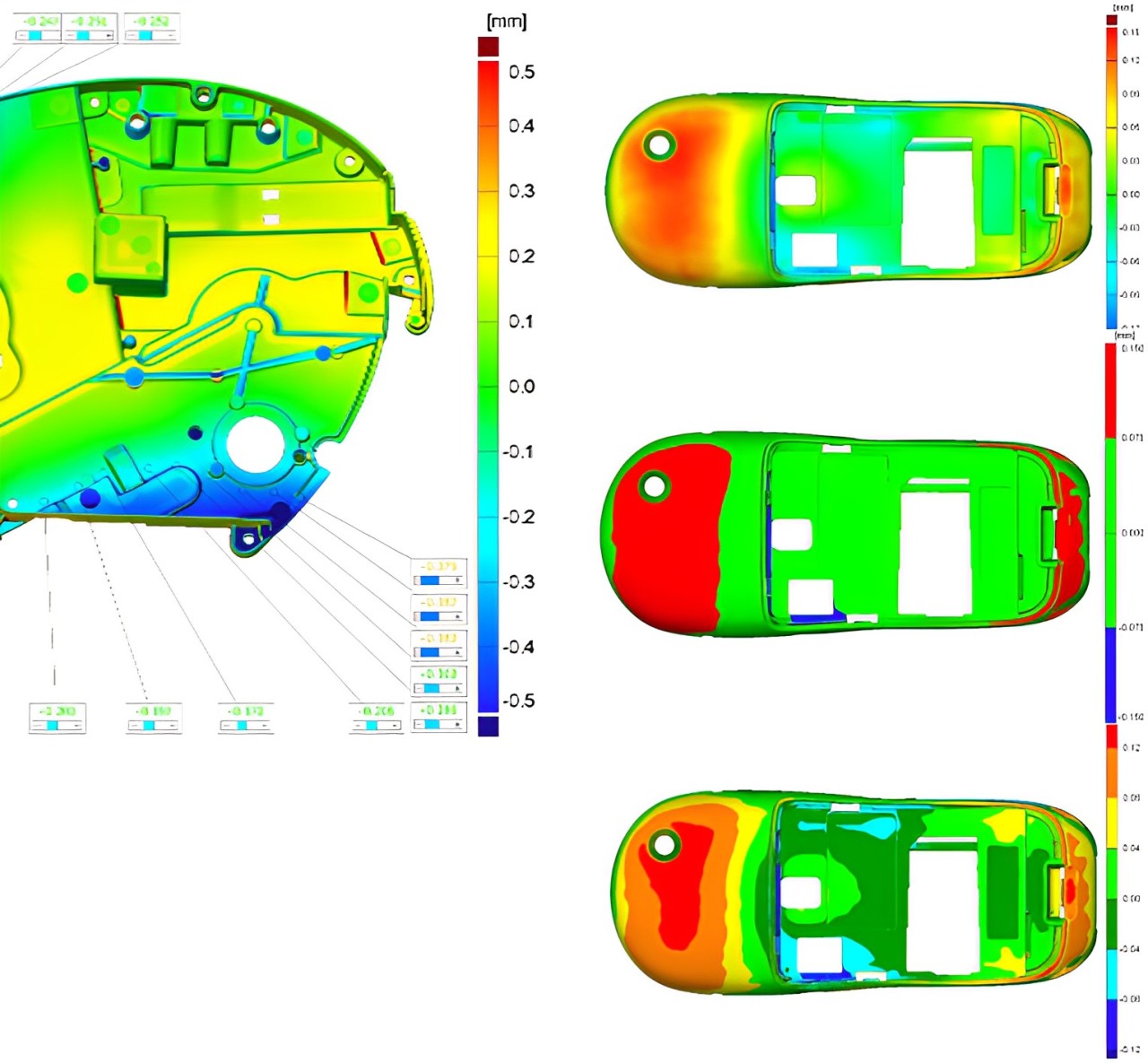

In industrial optical scanning, we use the ATOS series Compact Scan system to provide precise scans with detailed resolution at high speeds.

Three-dimensional digitizing and measuring systems provide solutions for sheet metal parts, equipment and molds, turbine blades, prototypes, injection molded parts, castings and more industrial parts.

Optical measurement technology and full-field surface measurement systems have become a standard tool in almost all industries. Optical measurement systems are now an indispensable quality control tool in modern product development and production process chains.

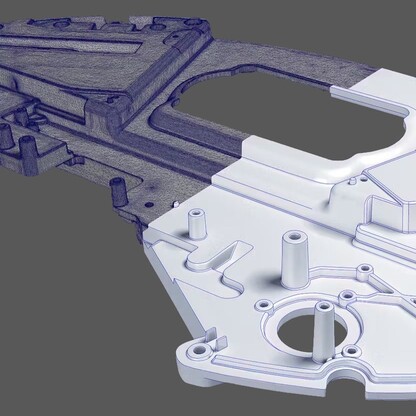

Reverse engineering is basically the measurement of the part or parts to be reverse engineered with the desired and required precision with various measuring devices, taking into account the size of the part or parts to be reverse engineered, and then re-extracting these dimensions in CAD programs. After the necessary processes are completed, the desired and necessary changes are made on the part, and even afterwards, this part can be mass-produced or specially produced and put into use. Reverse engineering is an indispensable part of innovation, which is also an indispensable mechanic of the sector we are in as a company. Reverse engineering saves a lot of time, money, power and resources.

Product design and industrial modeling are processes used to improve the aesthetic and functional characteristics of a product.

Product design and industrial modeling is the process of transforming an idea into a tangible product. This discipline combines creativity, engineering knowledge and aesthetic understanding to create innovative and functional products.

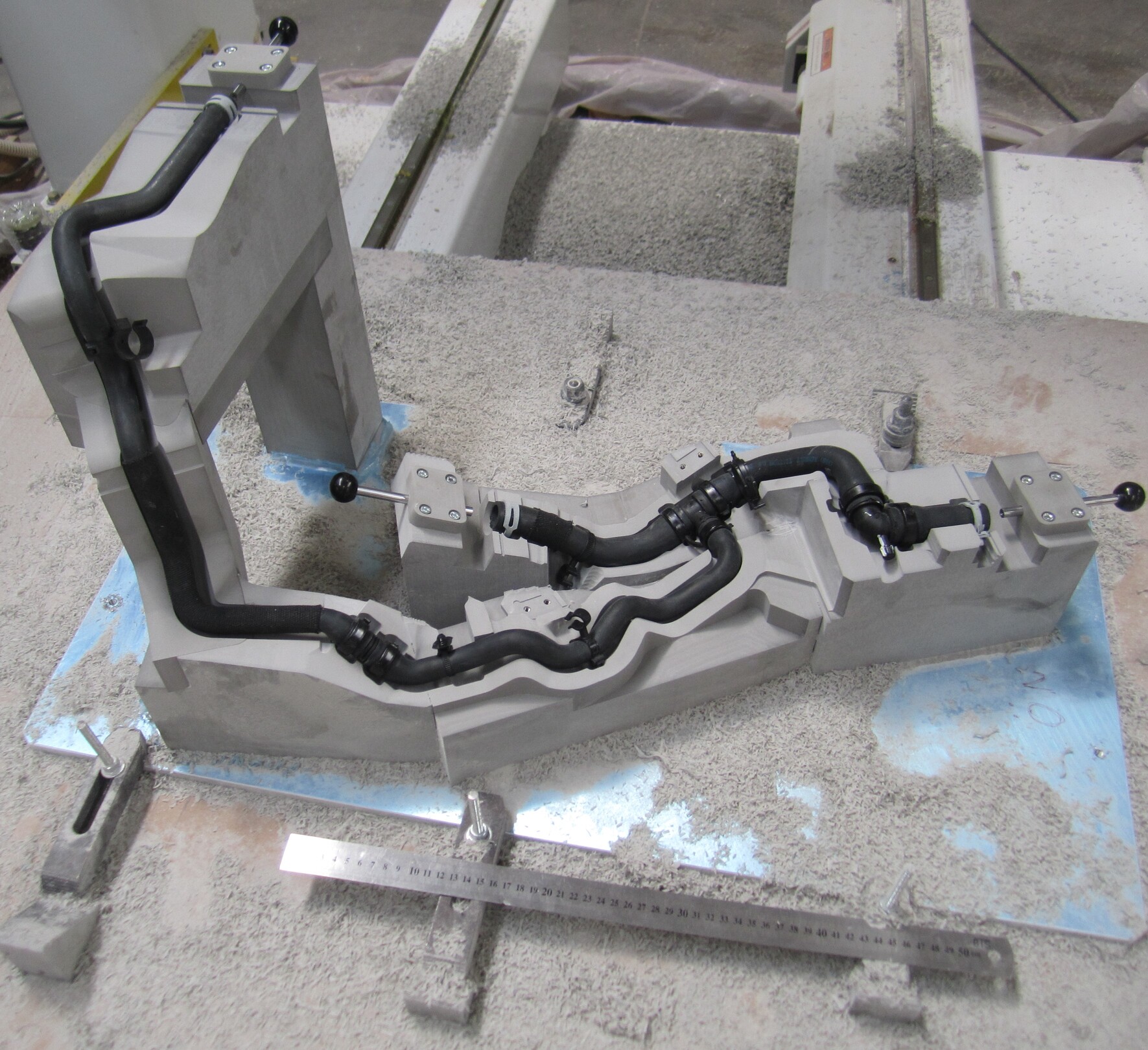

Fixtures and jigs are used extensively in mass production.

One method of reducing the production cost per component is to reduce machining cycle times. To reduce manufacturing cycle times, non-production time such as loading, unloading and placing the part on the machine must be reduced. This is why fixture and jig designs are so important. The productive time of a machine is the time required for the machine to cut metal.